The Value Offline Digital Finishing Brings to Your Business

Support the second step in your production process in the most efficient way possible. All slitting, stripping, cutting and flexographic embellishment needed to make your digital work “pop” is achieved in a single run

50% faster changeovers and production level speed up to 1000 fpm coupled with industry-setting lead times from Rotoflex manufacturing make this the fastest comprehensive solution on the market

Deliver differentiated product to customers cost effectively. Print station and rail feature options unlock finishes once out of reach without downtime associated with ancillary machinery

Rail system ensures variability for future retrofits that integrate new decoration and finishing options

Operator-friendly infrastructure and intuitive design ensures simple training process and job-to-job consistency

Backed by global service and technical specialists that understand digital workflows and what can help you remove production bottlenecks

Product Overview Video

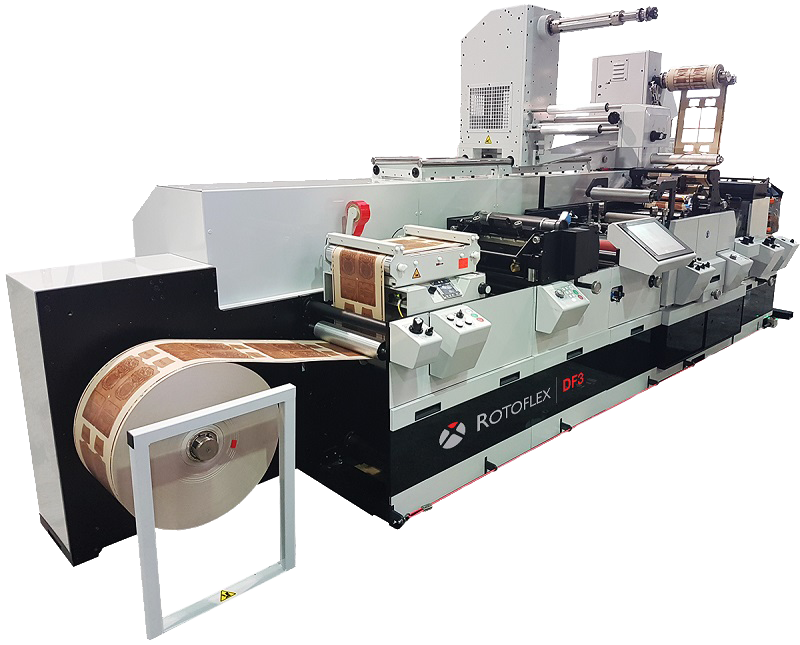

Rotoflex DF3 is a highly-configurable offline digital finishing and converting solution.

Technical Specifications

Web Width

13.5 inches (340 mm)

Speeds

750 fpm (228 mpm) for full rotary

360 fpm (110 mpm) for semi-rotary

Die Cylinder Repeat

10 – 26 inches (254 – 660 mm) solid rotary

Magnetic Die Cylinder Repeat

Up to 26 inches (660 mm) for semi-rotary applications

Flex Plate Repeat

2 – 25 inches (50 – 635 mm) when utilizing semi rotary diecutting

Print Width

13 inches (330 mm) with an open design and ergonomic lock-and-load features

Curing

The opportunities are endless to support your pressroom curing preferences.

Incorporate high-efficiency hot air, UV LED, or UV systems

Mandrels

Standard 3 inch (75 mm)

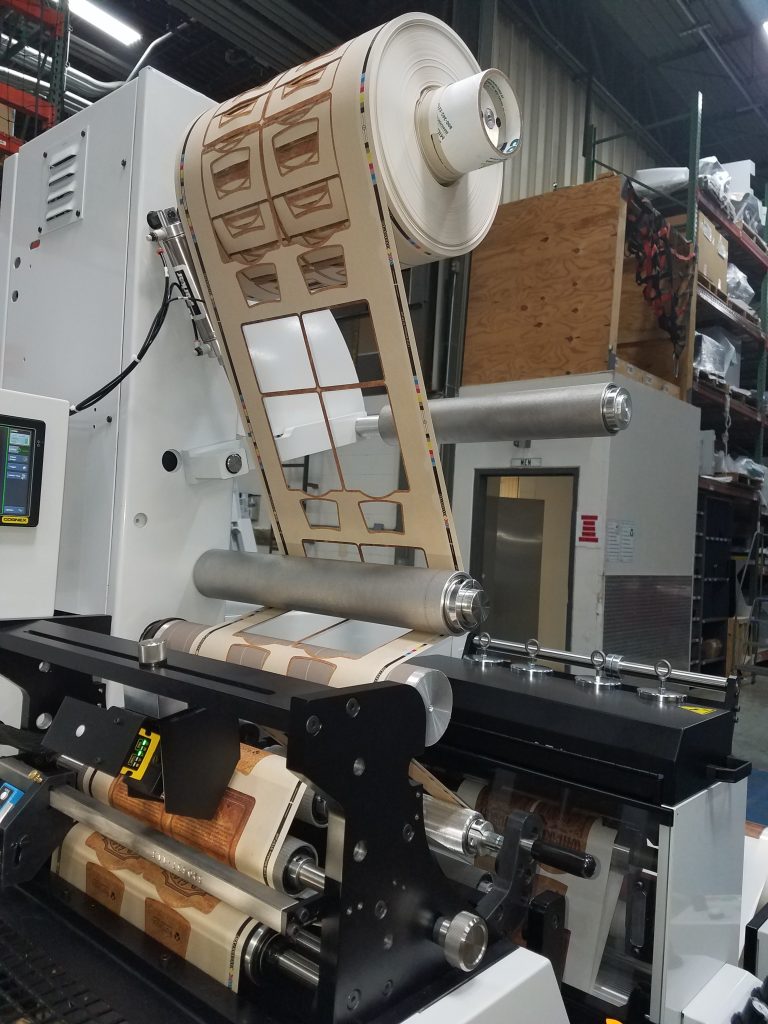

Converting Options

Dry or Wet Lamination

Embossing

Flexographic Spots

Varnish

Cold & Hot Foil Stamping

-Rotary Screen or Modular Digital Alternative to rotary screen

Finishing Options

Lamination Rewind

Trim Removal

Sheeter & Conveyor Table

Flag & Splice Detection

Multi-Lane and Clear-on-Clear Label Counting

Additional Configuration Options

Report Management System (RMS) Production Analysis Tool

Missing Label & Matrix Detection

Vision Inspection System

RFID Insertion

Unsupported Film Kits

Complimentary Processes

Complements digital, non-hybrid label presses without inline converting functionality.

Eliminates need for single-application embellishment units.

Ideal replacement for legacy digital converting solutions.

Support Your Digital Print. Better and Faster.

Brands need flexibility with the finishes they put on labels. That's where the DF3 comes into play as your production phase 2. The Rotoflex DF3 is a robust multi-function platform for finishing printed label and film stock.

The system is extremely flexible, offering a continuous or semi-rotary mode to accommodate a wide range of repeat sizes, while also modular to adapt to the embellishment needs of a demanding digital market.

PMS Spot Colors

PMS Spot Colors Lamination

Lamination Embossing

Embossing Cold & Hot Foil

Cold & Hot Foil Rewind

Rewind Semi-Rotary Diecutting

Semi-Rotary Diecutting Slitting & Stripping

Slitting & Stripping Tactile Effects

Tactile Effects Varnish

Varnish